TORR 150 Servo DriveHigh Production Fully Automatic Bag-In-Box

Filling Machine for Bags

Fills Bag-in-Box (BIB)

Automatic Bag and Pouch Filler for High-Volume Liquid Packaging

The TORR Model 150 is a fully automatic bag-in-box filler designed for high volume, high speed, 24/7 liquid packaging production. It takes bags in web format and feeds them spout leading to the fill head. The bags are separated from the web before filling. The filler can be integrated with TORR automatic bag-into-box loading systems for packs from 1.5 liters up to a 20-liter capacity.

Sanitary Filling and Sealing

The 150 Bag-In-Box filler is a fully automatic liquid bagging machine constructed of stainless steel and engineered plastics for long life and sanitary clean-up. Tooling is available for all caps and bags on the market. The optional fill head is purged with nitrogen and virtually eliminates O2 contamination of liquids.

- Easy-to-use 10 inch touch screen operator interface

- Automatic feed and separation of web bags

- Electric and pneumatic panels are easily accessible and fully sealed.

- Optional powered conveyor moves boxes automatically to bag into box loader

- Optional C1 D2 Explosion Proof rating

- Automatic filling machine fills bags from 1.5 to 20 Liters

- Optional fill head shrouds with nitrogen for low dissolved oxygen fills

- Optional pressurized product balance tank for accurate bag filling and sealing

- Optional product pumps

150 Spec Brochure pdf

150 Spec Brochure pdfCall 530-247-6909 for pricing, info or inquiring about higher volume systems

Model 150 Automatic Liquid Packaging Machine Benefits

TORR’s automatic liquid packaging solutions include the following benefits:

High Volume Production

Fills 3 liter bags at 15-18 bags per minute

Bag-in-Box Fills

Fills bags for bag-in-box products up to 20 liters.

Nitrogen Purge System

Optional fill head shrouds use Nitrogen to purge oxygen from the fill head area.

Automatic Liquid Filling Machine Comparison

See how the Model 150 filling system stacks up against other TORR automatic liquid filling machines.

| Model | Pouch | Bag | Both | Purge | Rate |

|---|---|---|---|---|---|

| TORR 145 (Pouch) | 15-18 BPM | ||||

| TORR 150 | 15-18 BPM | ||||

| TORR 180 | 20-25 BPM |

Key Product Features

Patent Pending Fill Valve

Eliminates drips and dribbles, achieves Low Dissolved Oxygen (DO) while simultaneously increasing shelf life with Nitrogen Purge and Vacuum control technology.

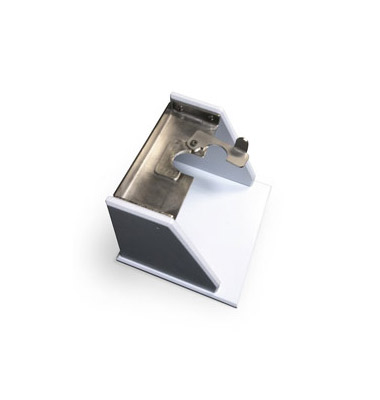

Servo Drives

Our servo drives allow our fillers to run accuratley and reliably around the clock in the most demanding environments.

Optional Balance Tanks and Loaders

TORR offers both balance tanks and loades for turnkey production lines.

Air Pad Oxygen Control

The air pad closes off the spout from below just prior to re-capping to minimize the amount of air entering the bag.

Touch Screen Panel View

Controls fill weights, adjust fill sequence and troubleshoot from the touch screen control panel.

Automated Bag Locking and Ejection

Bag gripper latch locks close during filling and automatically ejects the bag or pouch after fill cycle